8 Vertical Lifelines and Fall Arrestors

Lifeline

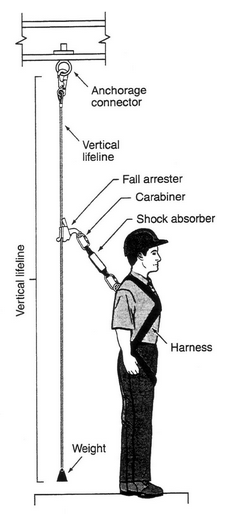

A lifeline is a vertical line that is attached to a fixed anchor point or a static line. Lifelines must comply with the latest versions of CSA Z259.16: Design of Active Fall-Protection Systems and CSA Z259.2.1: Fall Arrestors, Vertical Lifelines and Rails.

Lifelines must:

- be made of synthetic fibres consistent with Polyamide or Polyester

- have a breaking strength of not less than 27kN or 6075 pounds

- be free of splices and knots except at the terminations

- avoid contact with sharp edges and abrasive surfaces

- be 16 mm (5/8”) diameter

Fall Arrestor

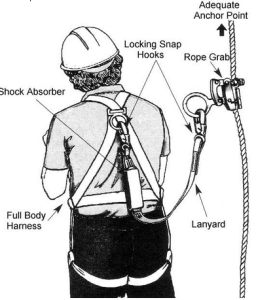

A fall arrestor, or ropegrab, is a device that travels along a lifeline and will lock securely onto the lifeline in the event of a fall. It is recommended that lanyards used with ropegrabs be kept as short as possible. When practical, position ropegrabs at or above shoulder height to reduce free-fall distance. Remember, if the free-fall distance may exceed 1.22 metres (4 feet), an energy absorber must also be used. Inspect the rope grab before each use. Make sure the device is suitable for the diameter of rope you’re using. Check for deformities and excessive wear. Test the mechanism to make sure it works properly.

Fall arrestors shall not come off the lifeline when moved up or down. They are manufactured in two different configurations:

- Automatic (Class AD or ADP or

- Manual (Class MDP)

Horizontal Lifeline

- Designed by a professional engineer who specializes in fall arrest systems, or

- A pre-manufactured system installed in accordance with the manufacturer’s instructions

Two CSA standards apply:

- CSA Z259.16: Design of Active Fall-Protection Systems

- CSA Z259.13: Flexible Horizontal Lifeline Systems

In a fall, extreme forces are applied to the anchor points of a horizontal lifeline. A professional engineer must design the system to safely absorb those forces.

Apply the Hierarchy of Control when determining how hazards will be best controlled. Record the results of the site hazard assessment. Forms for this purpose are available from many sources.

Fall Hazards and Impacts

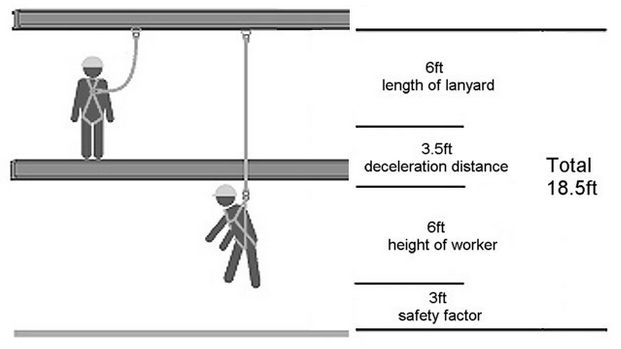

Total Fall Clearance

It is required that you have at least 18.5 feet of unobstructed fall distance between your anchor point and the next lower level when using a 6-foot energy absorbing lanyard*. An energy absorbing lanyard that is 6 feet long, hook-to-hook, may elongate to 9 ½ feet or more when subjected to an impact load. Add this distance to the height of the person working (typically 6 feet). The lanyard has the potential to stretch, and the harness may not fit properly, so add another 3 feet for a safety factor.

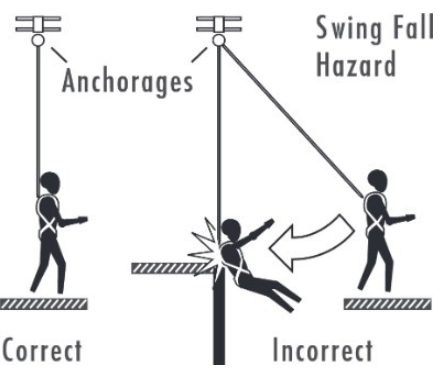

Swing Fall

Swing, or pendulum falls can result in significant injuries. When the anchor point is not directly above the worker at the onset of the fall, the worker will initially travel straight down until tensioning of the fall arrest system occurs. Then, the fall victim will begin a swing fall which will subsequently bring him/her under the anchor point and beyond. If there are any objects in the path of this swing fall, the victim will strike them. The NS Workplace Health and Safety Regulations require that swing falls be minimized, and that the distance a person drops during the swing is limited to a maximum of 1.2 m.

To reduce swing falls:

- Consider using portable anchorages.

- Consider using a horizontal lifeline (in accordance with CSA Z259.16: Design of Active Fall-Protection Systems and CSA Z259.13: Flexible Horizontal Lifeline Systems.

- When selecting anchorages, adopt measures to minimize the swing fall, or position the anchor in such a way that the swing fall would take the fall victim away from, and not in the direction of, the side objects.

- Follow manufacturers’ specifications for all fall protection equipment.

Other Fall Hazards

A wide range of other hazards may exist and they need to be assessed. These may include environmental factors (e.g. wind, rain, ice, stinging insects), tripping hazards, falling objects and others.