10 Workplace Sanitation

Maintaining a clean work environment is critical in preventing foodborne illness. Bacteria can grow on unsanitary surfaces and then contaminate food. Just because a work surface looks clean does not mean that it is sanitary. Always ensure that you clean and sanitize a work area before starting to prepare food.

Cleaning Procedures and Schedules

Cleaning with soap and other detergents is just one step of the cleaning procedure. It is also necessary to sanitize. Cleaning will remove any dirt or grease, but will not necessarily kill any bacteria or other pathogens. Only a sanitizer will kill bacteria and ensure the area is safe for food preparation. Leading sanitizers used in the food service industry are chlorine solutions (bleach), quaternary solutions (quats), and iodine. Use these materials according to the manufacturer’s instructions that accompany the product and that are found on the material safety data sheet (MSDS) using the appropriate personal protective equipment.

A sanitation plan is important in any food service preparation area. It ensures that all surfaces are cleaned on a regular basis and reduces the risks of transferring bacteria or other pathogens from an unclean surface to clean equipment such as cutting boards or tools. A sanitation plan has two components:

- A list of cleaning and sanitizing agents or supplies with instructions on their safe use and storage

- A cleaning schedule, outlining how each item needs to be cleaned, who is responsible, and how frequently it happens

Figure 5 shows a sample daily and weekly cleaning schedule for a restaurant.

Figure 5. Sample Cleaning Schedule

| Item | Frequency | Method | Responsibility | Supervisor initial |

|---|---|---|---|---|

| Upright mixer |

|

|

Pastry cooks | ________ |

| Meat slicer |

|

|

Garde manger | ________ |

| Item | Frequency | Method | Responsibility | Supervisor initial |

|---|---|---|---|---|

| Dry storage | Monday after dinner service |

|

Grill cook | ________ |

| Reach-in freezer | Tuesday after dinner dervice |

|

Garde manger | ________ |

Dishwashing Procedures

Effective dishwashing ensures that all equipment is sanitary and ready for use when required. Using soiled or dirty china is not only dangerous, but it will tell customers that the operator as little or no regard for customer safety. Table 2.5 shows the proper procedures for both manual and automatic dishwashing.

Before washing, scrape dishes and pre-soak any items with hard to remove residue. Then follow the procedure in Table 5, depending on whether you are using a high- or low-temperature dishwasher or you are washing dishes manually.

| Step | Manual | High-temperature dishwasher | Low-temperature dishwasher or glass washer |

|---|---|---|---|

| Wash | Use a commercial detergent and 45°C (113°F) water. | Wash cycle must reach at least 60°C (140°F). | Wash cycle must reach at least 60°C (140°F). |

| Rinse | Rinse in clean hot water. | Hot rinse cycle. | Warm or cold rinse cycle with sanitizer. |

| Sanitize | Sanitize for 2 minutes with an approved sanitizing solution (50 ppm chlorine or 12.5 ppm iodine). | Rinse cycle must reach at least 82°C (180°F) for at least 10 seconds. | Final rinse must have concentration of 50 ppm chlorine or 12.5 ppm iodine. |

| Dry | Drain boards should be sanitized and sloped for drainage.

Never towel dry. |

Drain boards should be sanitized and sloped for drainage

Never towel dry. |

Drain boards should be sanitized and sloped for drainage

Never towel dry. |

Routine Equipment Maintenance

Most kitchen equipment is intended to be disassembled for cleaning. Refer to the manufacturer’s instructions and training provided by your employer or instructor on how to do this safely. Some equipment is intended to be cleaned in place. This should be identified in your sanitation plan and cleaning schedule.

All equipment must be routinely cleaned and inspected. Older equipment may have nooks and crannies where dirt and bacteria can hide, which can be difficult to clean effectively. Proper cleaning procedures must be established and followed at all times with regular review to ensure that procedures are working. If equipment is replaced or cleaning materials change, the process may have to be adjusted. If you notice any safety concerns with the equipment while cleaning it, such as a frayed cord, missing guard or loose parts, let your supervisor know immediately.

Importance of Personal Hygiene

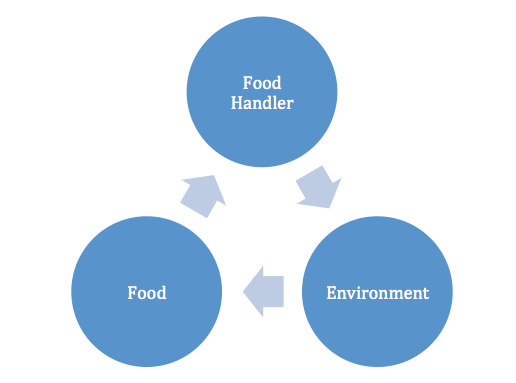

It is imperative for safe food-handling outcomes for all workers to be familiar with standard sanitation and hygiene practices. Figure 6 shows the cycles of transmission of micro-organisms. One of the basic principles is to break the cycle by avoiding cross-contamination, which can be achieved by ensuring personal hygiene practices are followed.

Proper personal hygiene is critical in any food service premise. Personal hygiene includes:

- Showering and bathing regularly

- Keeping hair clean hair and covered or tied back

- Keeping clean clothing and footwear that is used only at work

- Handwashing regularly

- Using clean utensils for tasting food

- Using separate cloths for cleaning and wiping plates

Handwashing

Proper and regular handwashing is a critical part of any food safety system. You must always wash your hands after:

- Sneezing, coughing, or touching your mouth or nose

- Using the bathroom

- Smoking or using toothpicks

- Handling raw foods

- Cleaning and wiping tables, food preparation surfaces, or equipment

- Handling soiled objects, garbage, or money

The steps for proper handwashing are as follows:

- Wet hands with warm water.

- Apply liquid soap and lather for at least 20 to 30 seconds.

- Scrub backs of hands, wrists, all fingers, and under nails.

- Rinse under running water, pointing down toward the drain.

- Dry with a paper towel.

- Turn off taps and open bathroom door using the paper towel.