4.8 The Sequential Processes and the Bottleneck

Sequential processes are characterized by a series of steps performed in a specific order, where the output of one step becomes the input for the subsequent step. A classic example of such a process is the manufacturing assembly line, where each workstation receives inputs from the preceding workstation and passes its outputs to the next workstation. In these processes, it is typically assumed that each step is performed by a dedicated staff member, as is the case in assembly line operations.

In sequential processes, achieving a balanced cycle time across all steps is crucial. In other words, there should be minimal variation in the time required for different steps to process one unit of product. For instance, if step 1, step 2, and step 3 take 3, 10, and 5 minutes, respectively, to process one unit of product, two major issues can arise during production:

- Inventory Accumulation: Since step 1 is significantly faster than step 2, products that have already been processed in step 1 will accumulate before step 2, waiting for their turn to be processed. This leads to a buildup of work-in-process inventory, which can be costly due to inventory holding costs and potential quality issues.

- Resource Idleness: Step 3 will consistently need to wait for step 2 for an additional 5 minutes. This is because step 3 completes its work on the current unit in 5 minutes, but step 2 requires 10 minutes to finish its task and feed the output to step 3. As a result, step 3 experiences prolonged periods of idleness, which is costly for the company. Despite paying the staff assigned to step 3 for the entire duration, their productive output is reduced due to the slow input rate from step 2.

The root cause of these issues is the presence of a bottleneck, which is the step with the longest cycle time (in this case, step 2). The bottleneck effectively constrains the overall throughput of the entire process, leading to inefficiencies such as inventory buildup and resource idleness.

It is essential to identify and address the bottleneck step to optimize sequential processes. This may involve capacity expansions, process improvements, or alternative resource allocations to balance the cycle times across all steps. Organizations can improve process flow, reduce waste, and enhance overall operational efficiency by eliminating or mitigating the bottleneck.

Image Description

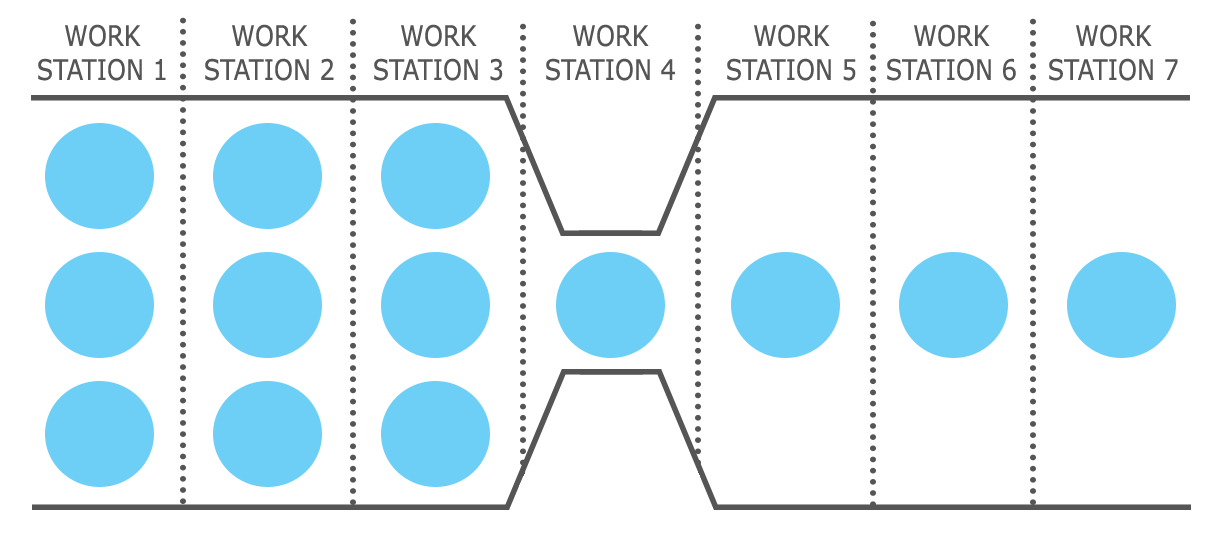

The image is a diagram of seven workstations arranged horizontally.

- Workstations 1 to 3 are on the left side, each containing three blue circles arranged vertically, indicating multiple tasks or items at each station.

- Workstation 4 is in the center and has a funnel-like shape, narrowing towards the middle, with one blue circle, suggesting a bottleneck or a point of convergence.

- Workstations 5 to 7 are on the right side, each containing one blue circle, indicating fewer tasks or items per station compared to Workstations 1 to 3.

The diagram visually highlights the congestion at Workstation 4, demonstrating that while the initial workstations handle multiple tasks, the central workstation significantly limits throughput before tasks continue to the final stations.

“7 Strategic Capacity Planning” from Introduction to Operations Management Copyright © by Hamid Faramarzi and Mary Drane is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License, except where otherwise noted.—Modifications: used section The Sequential Processes and the Bottleneck, some paragraphs rewritten; added additional explanations.