1.2 Transformation Processes

Video: “What is Operations Management?” by Frankfurt School of Finance & Management [1:35] is licensed under the Standard YouTube License. Transcript and closed captions available on YouTube.

A transformation process is any activity or group of activities that takes one or more inputs, transforms and adds value to them, and provides outputs for customers or clients. Where the inputs are raw materials, it is relatively easy to identify the transformation involved, such as when milk is transformed into cheese or butter. Where the inputs are information or people, the nature of the transformation may be less obvious. For example, a hospital transforms ill patients (the input) into healthy patients (the output).

Organizations often need to transform three types of input: materials, information, and customers. For instance, withdrawing money from a bank account involves handling information related to the customer’s account, physical materials like cheques and currency, and the customer. Similarly, providing medical treatment to a patient in a hospital requires considering the patient’s health status (the ‘customer’), the materials used in treatment, and relevant patient information.

These transformation processes can be grouped into four categories (Figure 1.2.1):

- Manufacture: This involves physically creating products, such as automobiles.

- Service: Service-oriented processes focus on treating customers or storing products, as seen in hospitals or warehouses.

- Supply: This category encompasses changes in ownership of goods, often observed in retail settings.

- Transport: Processes related to the movement of materials or customers, such as taxi services.

Manufacture

The physical creation of products, e.g. automobiles

Service

Treatment of customers, storage of products, e.g. hospitals, warehouses

Supply

Change in ownership of goods, e.g. retail

Transport

The movement of materials/customers, e.g. taxi services

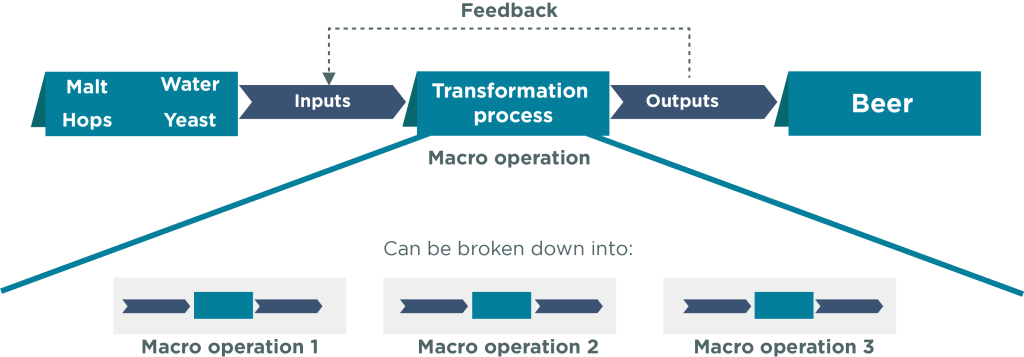

Several different transformations are usually required to produce a good or service. The overall transformation can be described as the macro-operation; the more detailed transformations within this macro-operation are micro-operations. For example, the macro-operation in a brewery is making beer, and the micro-operations involved in beer production are (Figure 1.2.2):

- Milling: Grind malted barley into grist.

- Mashing: Mix the grist with hot water to create wort.

- Fermentation: Add yeast to wort and ferment it into beer.

- Cooling and Transfer: Cool the wort and transfer it to the fermentation vessel.

- Filtering: Remove spent yeast from the beer.

- Packaging: Decant the beer into casks or bottles.

“1 Introduction to Operations Management” from Introduction to Operations Management Copyright © by Hamid Faramarzi and Mary Drane is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License, except where otherwise noted.—Modifications: used section The Transformation Process, added additional explanations.