7.1 Introduction

Supply Chain: A Collaborative Network

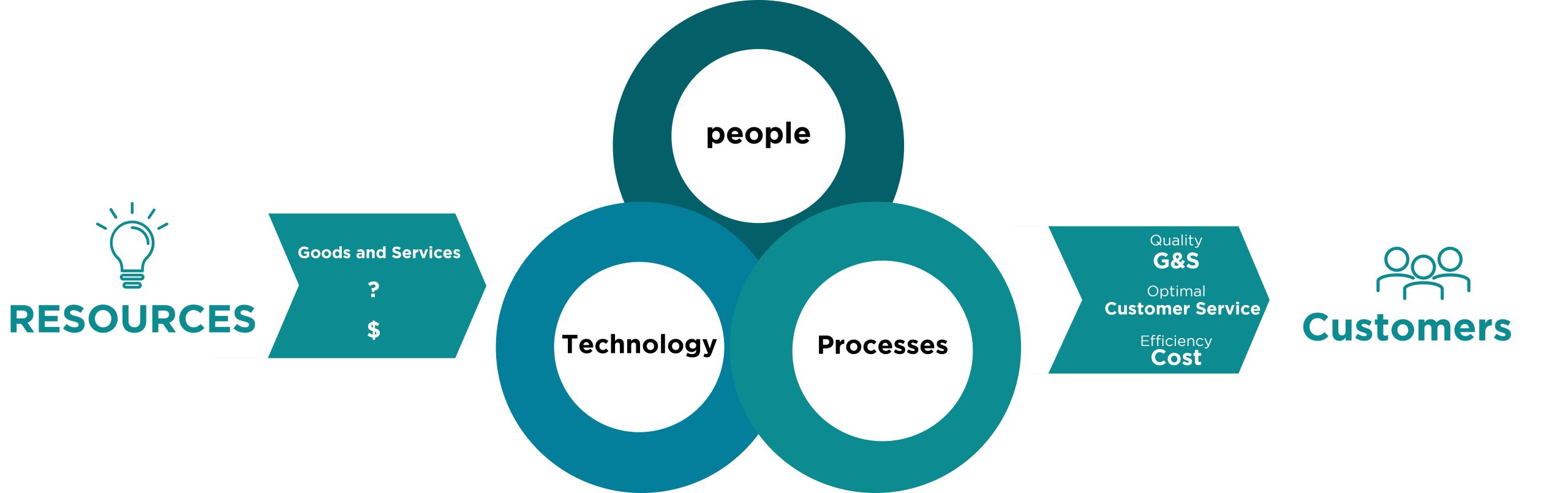

Supply chain refers to the interconnected network of organizations involved in fulfilling a customer order, from sourcing raw materials to delivering the final product. In contemporary marketplaces, customers demand quality goods and services, but not at high prices, and optimal customer service before and after they buy those products or services. They do not care how all this would be done for them, but on the other side of the spectrum, there are people with resources (goods, services, information, capital, etc.) that must be converted to the goods and services demanded in the market.

To make this possible, many participating operations would get involved, each connected with and adding value to the previous operations. The following figure shows that the elements linking these operations are people, processes and technology.

Each participant plays a crucial role in adding value for the end consumer. The supply chain encompasses suppliers, manufacturers, transporters, distribution centers, wholesalers, retailers, and end-consumers. Consider them as loops in a chain; if one operation does not add value to the previous one or does not support the next one, the chain will break.

The Strength of the Chain

The effectiveness of a supply chain is determined by its weakest link. This principle underscores the importance of supply chain management, which extends beyond a company’s internal operations. Organizations must actively collaborate with their supply chain partners to ensure optimal performance at every stage.

Ripple Effect of Inefficiencies

A weakness in any link of the supply chain can have far-reaching consequences. For instance, if a retailer fails to replenish inventory promptly, it can lead to product unavailability for end-consumers, resulting in lost sales. This ripple effect propagates upstream, with fewer orders placed with manufacturers and, consequently, reduced demand for raw materials from suppliers. Ultimately, the entire supply chain suffers financial implications due to a single weak link.

Collaborative Optimization

To mitigate such risks and maximize efficiency, organizations must adopt a collaborative approach to supply chain management. Regular communication and coordination with supply chain partners are essential to identify and address potential bottlenecks proactively. By fostering a culture of continuous improvement and leveraging advanced technologies, companies can optimize their supply chain operations, ensuring timely delivery of products and services while minimizing waste and maximizing customer satisfaction.

For example, if a retail store is not doing a good job at replenishing its inventory on time, the product will not be available to some end-consumers when needed, and as a result, lost sales happen, and that supply chain will be affected financially. Let’s think about it for a second: fewer products had been ordered from the manufacturer, and thus, fewer raw materials were ordered (by the manufacturer) from higher-tiered suppliers. This way, everybody in the supply chain sold less than they could if the retailer ordered the right quantity at the right time.

“Supply Chain” from Introduction to Operations Management Copyright © by Hamid Faramarzi and Mary Drane is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License, except where otherwise noted.—Modifications: some paragraphs rewritten; added additional explanations.