6.7 Grease Interceptors

ARTICLE 2.2.3.1. 5) of the NPC states that a Drum Trap shall not be used a fixture trap unless required to act as an interceptor. Drum traps may be used as interceptors for hair, lint, plaster, and jewelry.

ARTICLE 2.2.3.2. 1) states every interceptor must be designed so it can be readily

cleaned.

ARTICLE 2.2.3.2. 2) states every interceptor must be designed so that the interceptor does not become air bound. If air the air in the interceptor didn’t travel down the drain when waste was drained into the interceptor backpressure would be formed in the interceptor causing a restriction to the flow and a buildup of water on the upstream side.

ARTICLE 2.4.4.3. 1) states where a fixture discharging sewage that includes grease is located in a public kitchen, in a restaurant or in a care or detention occupancy, a grease interceptor shall be installed.

A pot sink in a commercial kitchen would probably require a grease trap, where a sink for hand washing wouldn’t.

ARTICLE 2.4.4.3. 4) states every interceptor shall have sufficient capacity to perform the service for which it is provided.

Grease problems are making headline news. FOG (fats, oils, and grease) have gummed up municipal sewer lines. Blockages of municipal sewer lines can result in raw sewage backing up into the basements of homes and businesses and many times this raw sludge seeps into our water tables polluting our waterways, rivers, and oceans.

According to the National Restaurant Association, total restaurant-industry sales have grown every year for the last 12 years, generating revenues of approximately $426 billion dollars, and the industry generates over three billion pounds of grease every year.

Many municipalities have bylaws limiting the discharge of FOG into the public sewer. Below is an excerpt from the HRM waste bylaw W101.

RESPECTING DISCHARGE INTO PUBLIC SEWERS

Halifax Regional Municipality By-Law W-101: Respecting Discharge into Public Sewers

5 – Grease, Oil, Sediment, Sand Traps or Interceptors[1]

- 5(1)Grease, oil, sediment and sand traps or interceptors shall be installed in all food service establishments or operations, vehicle service facilities, and car or truck washes when, in the opinion of the municipality, such a device is necessary for the proper handling and control of wastewater being discharged to the municipal wastewater facilities.

- 5(2) Traps or interceptors shall be installed such that they are easily accessible for all aspects of cleaning and inspection.

- 5(3) Traps or interceptors shall be maintained by the owner or operator in a condition of continuous efficient operation at the owner’s expense.

- 5(4) No retained or trapped oil, grease, sediment, sand, silt or other matter in any form shall be allowed to pass from the installed trap or interceptor into the wastewater facilities: instead, removal of retained or trapped materials shall be achieved by pumping or other physical means and shall be hauled away and disposed of as required by law.

- 5(5) Whenever an inspection of an installed trap or interceptor results in a written notice for action on the part of the person(s) responsible for the installed device, such action shall be completed within the compliance period granted by the written notice.

- 5(6) The owner or operator of an establishment shall provide the municipality, upon request, with the frequency of inspection and maintenance of any installed grease, oil, sediment and sand traps or interceptors as well as information as to the disposal method employed and location of hauled waste material.

- 5(7) Any reasonable request for inspection by the municipality shall be granted by the owner or operator of the establishment.

Large restaurants or kitchens may require interceptors of several hundred gallons capacity. Concrete interceptors are sometimes installed outside, underground.

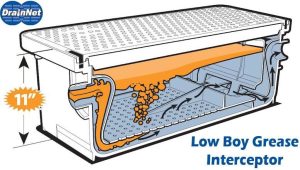

Grease traps

These are devices hooked directly to the outgoing drains of sinks and dishwashers and are located inside the restaurant. Because they hold captured grease, these traps must be emptied and cleaned on a regular basis, and the grease properly discarded to prevent grease overflow into the sewer system. There are a number of options to consider when you incorporate a grease interceptor into a commercial kitchen plumbing design. The most important design parameter is designing a system that will adhere to local building codes.

Grease traps do help prevent stoppages after the trap but blockages can (and do) occur as a result of insufficient grease trap line maintenance. A grease trap or drain line which is not periodically maintained will eventually clog.

Grease interceptor sizing

General Procedures:

Most manufacturers rate their interceptors in US gallons per minute.

To Determine the Flow Rate of Each Sink:

- Calculate the capacity of the sink in cubic inches

length x width x depth = __cu. in. - Convert the capacity from cubic inches to gallons per minute (GPM)

__cu. in. ÷ 231 = __US GPM.

Result is the flow rate required to drain the sink in one minute.

Example:

Three compartment pot sink, each compartment 12″ x 12″ x 15″

- 12″ x 12″ x 15″ = 2160 cu. in. x 3 comp. = 6480 cu. in.

- 6480 cu. in. ÷ 231 = 28 US GPM.

- 28 GPM

Note

If drain down time is not critical, for example the customer can wait 2 – 3 minutes for the sink to drain a smaller interceptor may be installed.

If the customer can wait 2 minutes than an interceptor rated at 14 US gallons per minute would work. If they can wait 3 minutes a 10 US gallon per minute interceptor would work.

It may not be recommended to pass a commercial dishwasher through an interceptor unless the interceptor is designed for the high temperature discharge water and the extra volume. Also local regulations may not allow commercial dishwashers to empty into an interceptor.

Sizing for Multiple Fixtures

- Determine the flow rate for each fixture to be serviced by the interceptor.

Some manufacturers reduce the second and third fixture volume by 50% and some recommend that no reduction to the volume at all, however you must review each manufacturers recommendations. - Result is the recommended flow rate of all fixtures draining to the interceptor.

Example

For this example, we will assume that the manufacturer recommends 100% of the largest fixture, 50% for the next largest and 25% for the remaining fixtures.

- Fixture A: 35 GPM Flow Rate

Fixture B: 26 GPM Flow Rate

Fixture C: 18 GPM Flow Rate

Fixture D: 12 GPM Flow Rate - 35 GPM (A) x 100% = 35 GPM

26 GPM (B) x 50% = 13 GPM

30 GPM (C + D) x 25% = 7.5 GPM

Total Flow Rate = 55.5 GPM

A 55 GPM interceptor is recommended for this installation.

Image Credit

- Drain Net Technologies LLC. (n.d.). Low boy grease trap cut-out. https://www.drain-net.com/grease-traps/grease-traps-15-75-gpm

- Halifax Regional Municipality. (2003). Respecting discharde into public sewers [ By-law -W-101.]. https://www.halifax.ca/sites/default/files/documents/city-hall/legislation-by-laws/By-LawW-101.pdf ↵