6.13 Commercial Washers

The following is only an example of part of an Installation Instruction Manual which would be required during the rough-in and finish stage of the plumbing. It is important to remember that each manufacturer will have their own set of instructions.

Installation of Drain Connection:

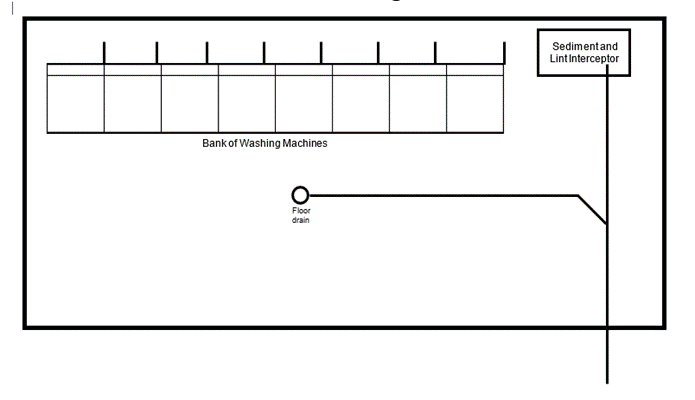

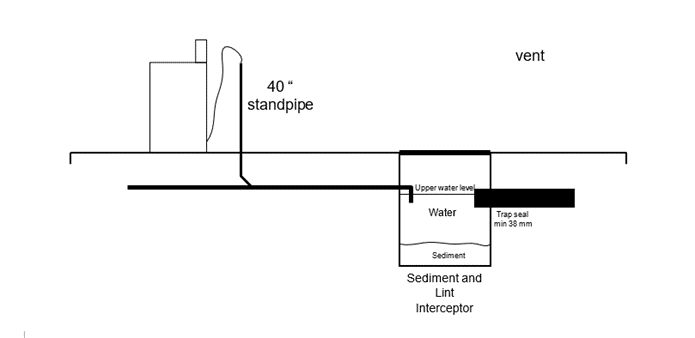

A drain system of adequate capacity is essential to machine performance. Ideally the water should empty through a 4-inch vented pipe directly into a sump or floor drain.

A flexible connection must be made to a vented drain system to prevent an airlock or siphon effect. On the tilt option models, a flexible drain hose must be provided of adequate length to compensate for tilting action of the machine. If proper drain size is not available or practical, a surge tank is required. A surge tank in conjunction with a sump pump should be used when gravity drainage is not possible, such as in below ground level installations.

Before any deviation from specified installation procedures is attempted, the customer or installer should contact the manufacturer. Increasing the drain hose length, installing elbows, or causing bends will decrease drain flow rate and increase drain time, impairing machine performance. If the drain arrangement is inadequate, the machine will not extract and will not discharge water properly.

Installation of Water Connection

Individual hot and cold plumbing lines with individual shut-off valves must be available to the machine. Hot water should be a minimum of 160F (70C). If lower temperature water is used the machine should be equipped for steam heating to heat the wash solution to the desired temperature. Best performance will be realized if water is provided at a pressure of 30-85 PSI. Although the machine will function properly at lower pressures, increased fill times will occur.

Flush the water system prior to initial use.

Use flexible hoses and install separate screen filters in the lines to keep rust and other foreign particles out of the solenoid valves. Hang the hoses in a large loop. Do not allow the hoses to kink. The water connections to the machine should be supplied by a hot and cold-water line of at least the sizes shown in the table below. Installation of additional machines will require proportional larger water lines.

To avoid potential water hammer in the water line, suitable devices to reduce the water hammer should be installed.

Installation of Steam Connection

Never touch internal or external steam pipes, connections, or components. These surfaces can be extremely hot and will cause severe burns. The steam must be turned off and the pipe, connections, and components allowed to cool before the pipe can be touched.

For machines equipped with optional steam heat, install piping in accordance with approved commercial steam practices. Failure to install the supplied steam filter may void the warranty.

Installation of External Chemical Supplies

Wear Eye and hand protection when handling chemicals. Always avoid direct contact with raw chemicals. Read the manufacturer’s directions for accidental contact before handling chemicals. Ensure that an eye-rinse facility and an emergency shower are within easy reach. Check at regular intervals for chemical leaks.

The following procedures must be observed when connecting any chemical injector to the washer-extractor. See the figure for a typical supply injection system setup.

Undiluted chemicals drips can damage the machine. Therefore, all chemicals supply dispenser pumps should be mounted below the washer’s injection point. All dispenser tubing should also run below the injection point. Loops do not prevent drips if these instructions are not followed. Failure to follow these instructions could damage the machine and void the warranty.

Commercial laundries may have a large variety of equipment such as washers and dryers including coin-operated, commercial feather cleaning, sterilizing machinery, ironers, dry-cleaning equipment pressing machines and rug cleaning,

Image Credit

- Unimac. (n.d.). Uw series hardmount washer-extractors. http://static.appliancesconnection.com/attachments/D1378840325.pdf