Chapter 4: Managing Firm Resources

Value Chain

Learning Objectives

- Define the primary activities of the value chain.

- Know the different support activities within the value chain.

- Be able to apply the value chain to an organization of your choosing.

- Understand the difference between a value chain and supply chain.

Elements of the Value Chain

When executives choose strategies, an organization’s resources and capabilities should be examined alongside consideration of its value chain. A value chain charts the path by which products and services are created and eventually sold to customers (Porter, 1985

The term value chain reflects the fact that, as each step of this path is completed, the product becomes more valuable than it was at the previous step (Figure 4.17 “Adding Value within a Value Chain”). Within the lumber business, for example, value is added when a tree is transformed into usable wooden boards; the boards created from a tree can be sold for more money than the price of the tree.

Value chains include both primary and secondary activities. Primary activities are actions directly involved in the creation and distribution of goods and services. Consider a simple illustrative example: doughnut shops. Doughnut shops transform basic commodity products such as flour, sugar, butter, and grease into delectable treats. Value is added through this process because consumers are willing to pay much more for doughnuts than they would be willing to pay for the underlying ingredients.

There are five primary activities.

Inbound logistics refers to the arrival of raw materials. Although doughnuts are seen by most consumers as notoriously unhealthy, the Doughnut Plant in New York City has carved out a unique niche for itself by obtaining organic ingredients from a local farmer’s market.

Operations centers on the production process of a good or service.

Outbound logistics tracks the movement of a finished product to customers. One of Southwest Airlines’ unique capabilities is moving passengers more quickly than its rivals. This advantage in operations is based in part on Southwest’s reliance on one type of airplane (which speeds maintenance) and its avoidance of advance seat assignments (which accelerates the passenger boarding process) and boarding from both front and rear of the airplane.

Attracting potential customers and convincing them to make purchases is the domain of marketing and sales. For example, people cannot help but notice Randy’s Donuts in Inglewood, California, because the building has a giant doughnut on top of it. Finally, service.

Service focuses on the extent to which a firm provides assistance to its customers. Voodoo Donuts in Portland, Oregon, has developed a clever website (voodoodoughnut.com) that helps customers understand their uniquely named products, such as the Voodoo Doll, the Texas Challenge, the Memphis Mafia, and the Dirty Snowball.

Support or secondary activities are all the actions not directly involved in the evolution of a product, but instead provides important underlying support for a primary activity. There are four main forms of support activities for most manufacturers.

Firm infrastructure refers to how the firm is organized and led by executives. The effects of this organizing and leadership can be profound. For example, Ron Joyce’s leadership of Canadian doughnut shop chain Tim Hortons was so successful that Canadians consume more doughnuts per person than all other countries. In terms of resource-based theory, Joyce’s leadership was clearly a valuable and rare resource that helped his firm prosper.

Also important is human resource management which includes activities involved in recruiting, training, and compensating employees. A recent research study used data from more than 12,000 organizations to demonstrate that how the level of knowledge, skills, and abilities of a firm’s employees can act as a strategic resource and strongly influence the firm’s performance (Crook et al., 2011). Certainly, the unique level of dedication demonstrated by employees at WestJet has contributed to that firm’s excellent performance over several decades.

Technology – The use of electronic devices, computer systems, and telecommunications to support primary activities. Although doughnut making is not a high-tech business, technology plays a variety of roles for doughnut shops, such as allowing customers to use debit cards, just in time delivery systems, online ordering, and supply management systems.

Procurement – The process of negotiating for and purchasing raw materials. Large doughnut chains such as Tim Hortons can gain cost advantages over their smaller rivals by purchasing flour, sugar, and other ingredients in bulk. Meanwhile, WestJet has gained an advantage over its rivals by using futures contracts within its procurement process to minimize the effects of rising fuel prices.

From the Value Chain to Best Value Supply Chains

“Time is money!” warns a famous saying. This simple yet profound statement suggests that organizations that quickly complete their work will enjoy greater profits, while slower-moving firms will suffer. The belief that time is money has encouraged the modern emphasis on supply chain management. A supply chain is a system of people, activities, information, and resources involved in creating a product and moving it to the customer. A supply chain is a broader concept than a value chain; the latter refers to activities within one firm, while the former captures the entire process of creating and distributing a product, often across several firms.

Competition in the 21st century requires an approach that considers the supply chain concept in tandem with the value-creation process within a firm: best value supply chains. These chains do not fixate on speed or on any other single metric. Instead, relative to their peers, best value supply chains focus on the total value added to the customer.

Creating best value supply chains requires four components. The first is strategic supply chain management—the use of supply chains as a means to create competitive advantages and enhance firm performance. Such an approach contradicts the popular wisdom centred on the need to maximize speed. Instead, there is recognition that the fastest chain may not satisfy customers’ needs. Best value supply chains strive to excel along four measures. Speed (or “cycle time”) is the time duration from initiation to completion of the production and distribution process. Quality refers to the relative reliability of supply chain activities. Supply chains’ efforts at managing cost involve enhancing value by either reducing expenses or increasing customer benefits for the same cost level. Flexibility refers to a supply chain’s responsiveness to changes in customers’ needs. Through balancing these four metrics, best value supply chains attempt to provide the highest level of total value added.

The value of strategic supply chain management is reflected in how firms such as Walmart have used their supply chains as competitive weapons to gain advantages over peers. Walmart excels in terms of speed and cost by locating all domestic stores within one day’s drive of a warehouse while owning a trucking fleet. This creates distribution speed and economies of scale that competitors simply cannot match. When Kmart’s executives decided in the late 1990s to compete head-to-head with Walmart on price, Walmart’s sophisticated logistics system enabled it to easily withstand the price war. Unable to match its rival’s speed and costs, Kmart soon plunged into bankruptcy. Walmart’s supply chains also possess strong quality and flexibility. When Hurricane Katrina devastated the Gulf Coast in 2005, Walmart used not only its warehouses and trucks but also its satellite technology, radio frequency identification (RFID), and global positioning systems to quickly divert assets to affected areas. The result was that Walmart emerged as the first responder in many towns and provided essentials such as drinking water faster than local and federal governments could.

Meanwhile, failing to manage a supply chain effectively causes serious harm. For example, in 2003 Motorola was unable to meet demand for its new camera phones because it did not have enough lenses available. Also, firms whose supply chains were centred in the Port of Los Angeles collectively lost more than $2 billion a day during a 2002 workers’ strike. In terms of stock price, firms’ market value erodes by an average of 10 percent following the announcement of a major supply chain problem.

The second component is agility, the supply chain’s relative capacity to act rapidly in response to dramatic changes in supply and demand (Lee, 2004). Agility can be achieved using buffers. Excess capacity, inventory, and management information systems all provide buffers that better enable a best value supply chain to service and to be more responsive to its customers. Rapid improvements and decreased costs in deploying information systems have enabled supply chains in recent years to reduce inventory as a buffer. Much popular thinking depicts inventory reduction as a goal in and of itself. However, this cannot occur without corresponding increases in buffer capacity elsewhere in the chain, or performance will suffer. A best value supply chain seeks to optimize the total costs of all buffers used. The costs of deploying each buffer differs across industries; therefore, no solution that works for one company can be directly applied to another in a different industry without adaptation.

Agility in a supply chain can also be improved and achieved by colocating with the customer. This arrangement creates an information flow that cannot be duplicated through other methods. Daily face-to-face contact for supply chain personnel enables quicker response times to customer demands due to the speed at which information can travel back and forth between the parties. Again, this buffer of increased and improved information flows comes at an expense, so executives seeking to build a best value supply chain will investigate the opportunity and determine whether this action optimizes total costs.

Adaptability refers to a willingness and capacity to reshape supply chains when necessary. Generally, creating one supply chain for a customer is desired because this helps minimize costs. Adaptable firms realize that this is not always a best value solution, however. For example, in the defense industry, the U.S. Army requires one class of weapon simulators to be repaired within eight hours, while another class of items can be repaired and returned within one month. To service these varying requirements efficiently and effectively, Computer Science Corporation (the firm whose supply chains maintain the equipment) must devise adaptable supply chains. In this case, spare parts inventory is positioned in proximity to the class of simulators requiring quick turnaround, while the less-time-sensitive devices are sent to a centralized repair facility. This supply chain configuration allows Computer Science Corporation to satisfy customer demands while avoiding the excess costs that would be involved in localizing all repair activities.

In situations in which the interests of one firm in the chain and the chain as a whole conflict, most executives will choose an option that benefits their firm. This creates a need for alignment among chain members. Alignment refers to creating consistency in the interests of all participants in a supply chain. In many situations, this can be accomplished through carefully writing incentives into contracts. Collaborative forecasting with suppliers and customers can also help build alignment. Taking the time to sit together with participants in the supply chain to agree on anticipated business levels permits shared understanding and rapid information transfers between parties. This is particularly valuable when customer demand is uncertain, such as in the retail industry (Ketchen et al., 2008).

Key Takeaways

- The value chain provides a useful tool for managers to examine systematically where value may be added to their organizations. This tool is useful in that it examines key elements in the production of a good or service, as well as areas in which value may be added in support of those primary activities.

Exercises

- If you were hired as a consultant for your university, what specific element of the value chain would you seek to improve first?

- What local business in your town could be improved most dramatically by applying the value chain? Would improvements of primary or support activities help to improve this firm most? Could knowledge of strategic supply chain management add further value to this firm?

References

Crook, T. R., Todd, S. Y., Combs, J. G., Woehr, D. J., & Ketchen, D. J. (2011). Does human capital matter? A meta-analysis of the relationship between human capital and firm performance concluded that there is a strong positive correlation. Journal of Applied Psychology, 96(3), 443–456.

Lee, H. L. (2004, October). The triple-A supply chain. Harvard Business Review, 83, 102–112.

Porter, M. E. 1985. Competitive advantage: Creating and sustaining superior performance. New York, NY: Free Press.

Ketchen, D. J., Rebarick, W., Hult, G. T., & Meyer, D. 2008. Best value supply chains: A key competitive weapon for the 21st century. Business Horizons, 51, 235–243.

Image descriptions

Figure 4.17 image description: Adding Value within a Value Chain

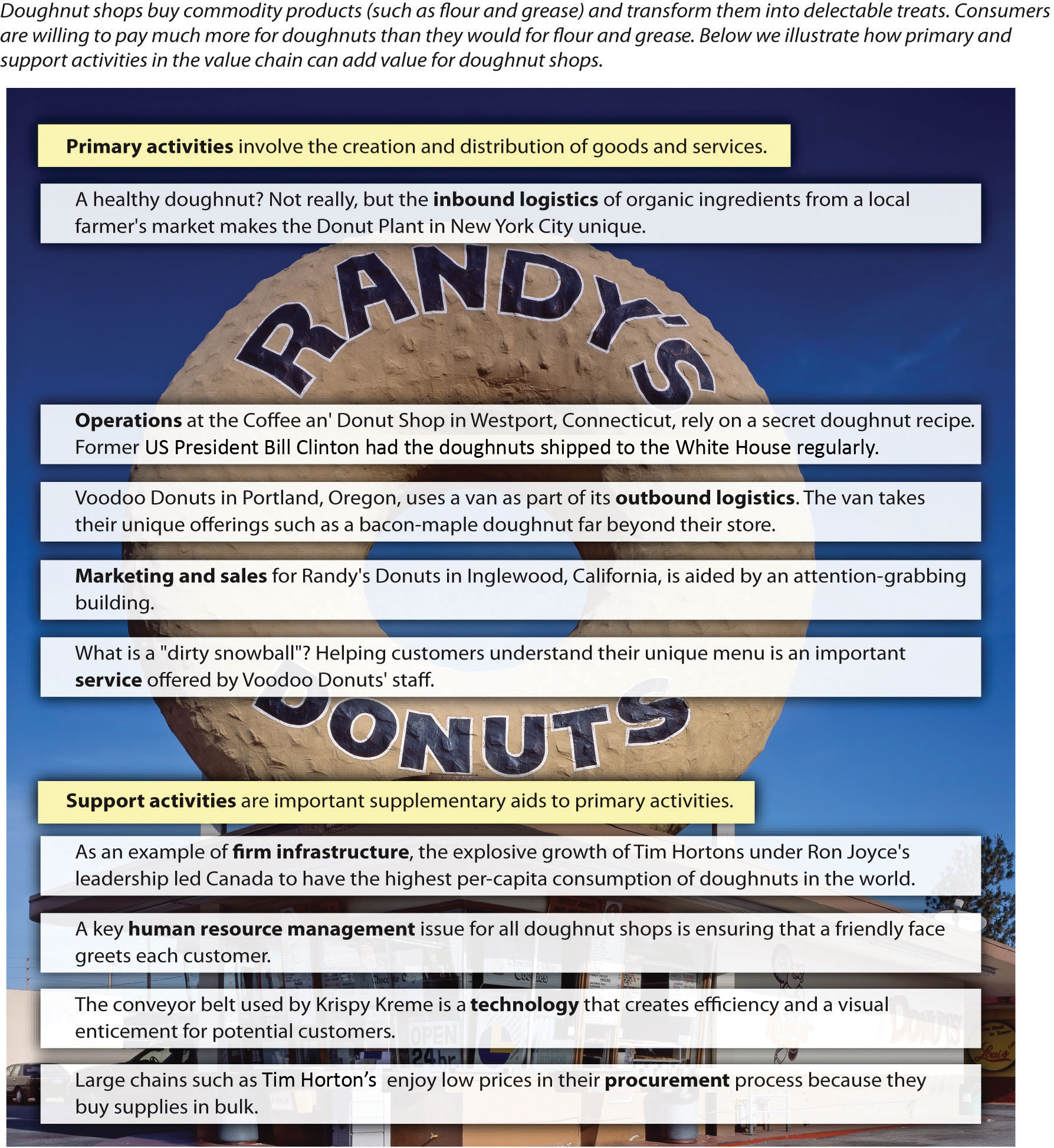

Doughnut shops buy commodity products (such as flour and grease) and transform them into delectable treats. Consumers are willing to pay much more for doughnuts than they would for flour and grease. Below we illustrate how primary and support activities in the value chain can add value for doughnut shops.

Primary activities involve the creation and distribution of goods and services.

A healthy doughnut? Not really, but the inbound logistics of organic ingredients from a local farmer’s market makes the Donut Plant in New York City unique.

Operations at the Coffee an’ Donut Shop in Westport, Connecticut, rely on a secret doughnut recipe. Former US President Bill Clinton had the doughnuts shipped to the White House regularly.

Voodoo Donuts in Portland, Oregon, uses a van as part of its outbound logistic: The van takes their unique offerings such as a bacon-maple doughnut far beyond their store.

Marketing and sales for Randy’s Donuts in Inglewood, California, is aided by attention-grabbing building.

What is a “dirty snowball”? Helping customers understand their unique menu is an important service offered by Voodoo Donuts’ staff.

Support activities are important supplementary aids to primary activities.

As an example of firm infrastructure, the explosive growth Of Tim Hortons under Ron Joyce’s leadership led Canada to have the highest per-capita consumption of doughnuts in the world.

A key human resource management issue for all doughnut shops is ensuring that a friendly face greets each customer.

The conveyor belt used by Krispy Kreme is a technology that creates efficiency and a visual enticement for potential customers.

Large chains such as Tim Horton’s enjoy low prices in their procurement process because they buy supplies in bulk.

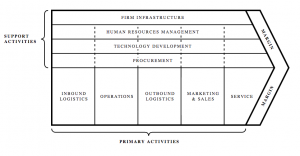

Figure 4.18 image description: The Value Chain

The primary activities of the value chain include inbound logistics, operation outbound logistics, marketing and sales, and service. Secondary activities or the support activities include firm infrastructure, human resources management, and procurement.

- This section of the chapter is adapted from Ketchen, D. J., Rebarick, W., Hult, G. T., & Meyer, D. 2008. Best value supply chains: A key competitive weapon for the 21st century. Business Horizons, 51, 235–243. ↵

A tool that charts the path by which inputs, including employees, create products and services for sale to clients & customers.

How the firm is organized and led by executives.

A system of people, activities, information, and resources involved in creating a product and moving it to the customer.

Supply chains that focus on the total value added to the customer as opposed to individual outcomes, such as speed or cost.

The use of supply chains as a means to create competitive advantages and enhance firm performance.

The time duration from initiation to completion of the production and distribution process.

The relative reliability of supply chain activities.

The price paid for supply chain inputs.

A supply chain’s responsiveness to changes in customers’ needs.

The supply chain’s relative capacity to act rapidly in response to dramatic changes in supply and demand.

A willingness and capacity to reshape supply chains when necessary.

Creating consistency in the interests of all participants in a supply chain.