The Challenge: Producing Quality Jetboards

The Challenge: Producing Quality Jetboards

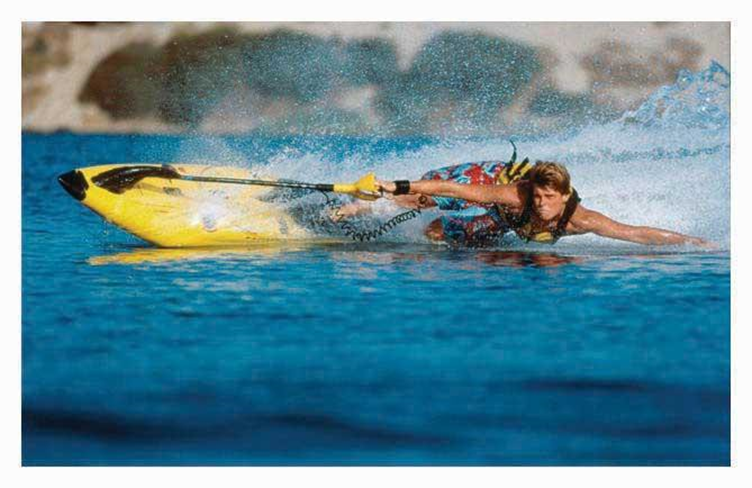

The product development process can be complex and lengthy. It took sixteen years for Bob Montgomery and others at his company to develop the PowerSki Jetboard, and this involved thousands of design changes. It was worth it, though: the Jetboard was an exciting, engine-propelled personal watercraft – a cross between a high-performance surfboard and a competition water-ski/wakeboard that received extensive media attention and rave reviews. It was showered with honours, including Time magazine’s “Best Invention of the Year” award.[1] Stories about the Jetboard appeared in more than fifty magazines around the world, and it was featured in several movies, over twenty-five TV shows, and on YouTube.[2]

Montgomery and his team at PowerSki enjoyed taking their well-deserved bows for the job they did designing the product, but having a product was only the beginning for the company. The next step was developing a system that would produce high-quality Jetboards at reasonable prices. Before putting this system in place, PowerSki managers had to address several questions.

- What kind of production process should they use to make the Jetboards?

- How large should their production facilities be, and where should they be located?

- Where should they buy needed materials?

- What systems will be needed to control the production process and ensure a quality product?

Answering these and other questions helped PowerSki set up a manufacturing system through which it could accomplish the most important task that it had set for itself: efficiently producing quality Jetboards.

- Time Magazine (2001). “Best Inventions of 2001: Motorized Surfboard.” Retrieved from: http://content.time.com/time/specials/packages/article/0,28804,1936165_1936240_1936351,00.html ↵

- Hydroforce Group LLC (2012). “Powerski Jetboards.” Retrieved from: http://www.powerski.com/content/psi_index.php ↵